World Class Cutting Solutions – Made in Germany

Paper Cutters

Fully automated, High speed cutting solutions.

Mobile Stacklifts

Ease operator fatigue and speed up production.

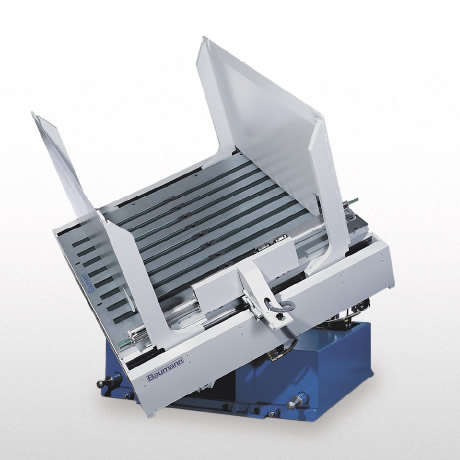

Automatic Joggers

Air and jogging for precise handling.

Automatic Loaders

Speed up production almost 300%.

Automatic Unloaders

Fully automate your cutting solution.

Pile Turners

Reduce Press Loading time, Manual and Fully Automatic.

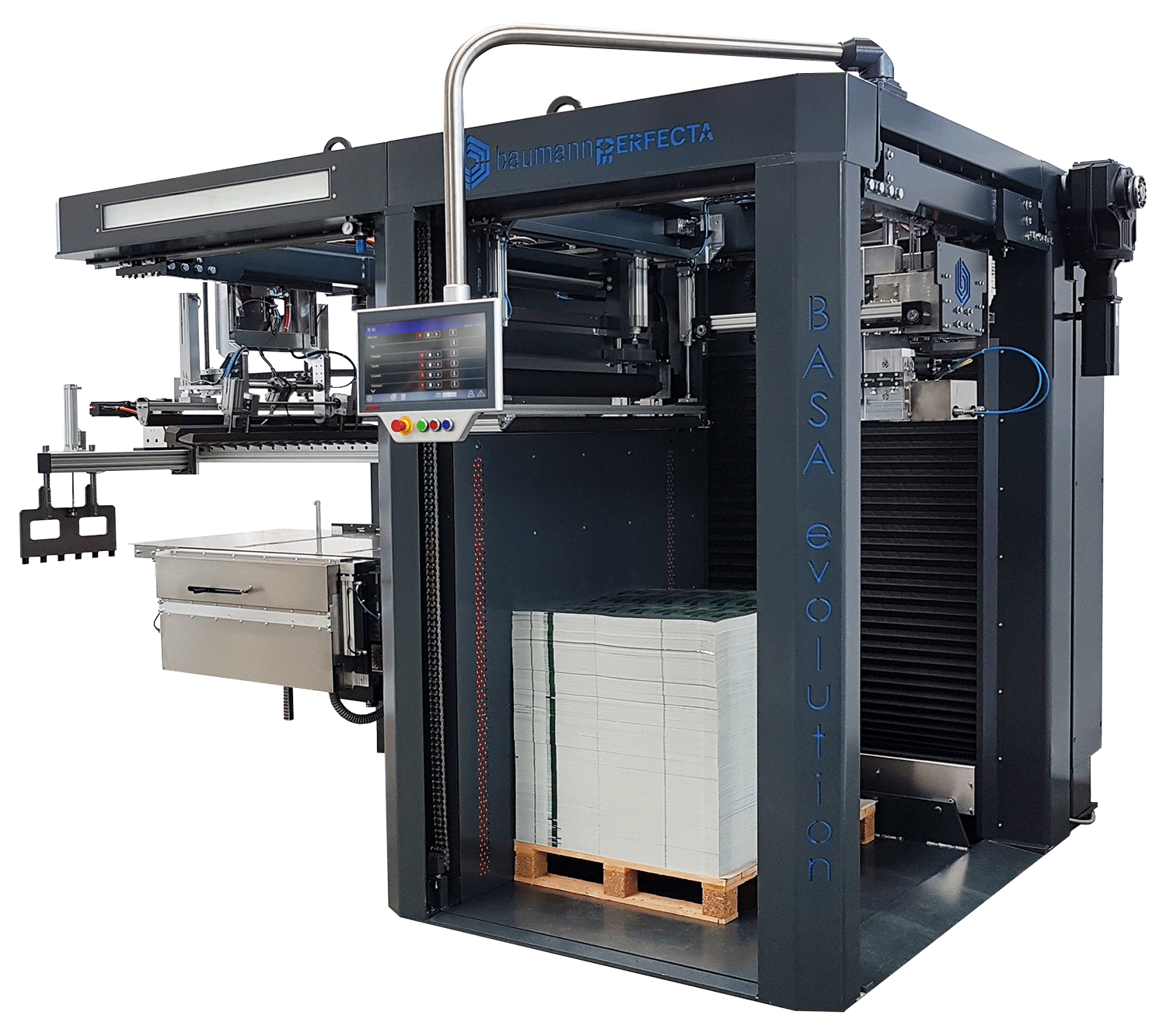

Fully Automatic Joggers

BASA evolution - The new low cost version for fully automatic jogging

Automatic Positioning System

For automatic transport, turning, and positioning of layers on the rear table of a cutting system. The BDG is the core component for a fully- or semi-automatic cutting process.

A BDG 10 can pick up a lift up to 60” x 80.7” at the loading point, turn it 90º or 180º, or move it onto the table of an Automatic Unloader BA 10- MULTI.

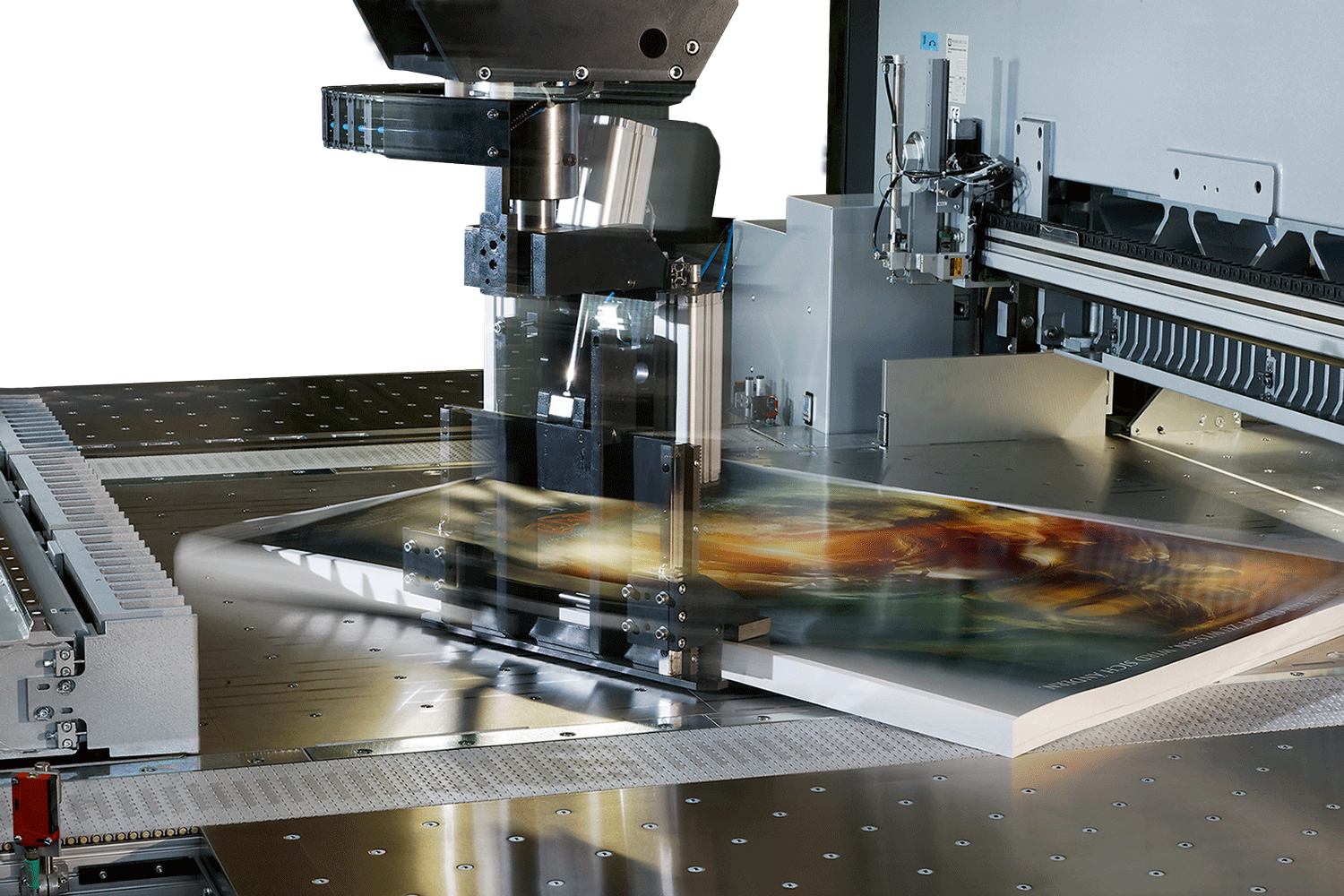

GRIPPER TRANSPORT SYSTEM BFS

For automatic transport of paper lifts to the guillotine. It is the connection link between automatic joggers or buffer spaces and the cutting system. The versatile gripper system BFS is often used in combination with paddle pusher systems BTE for loading material onto the rear or front table of the cutter.

PUSHER SYSTEM BTE

For automatic transport of paper lifts. The pushing unit BTE can unload automatic joggers, pressing stations, or automatic loaders and move the material onto the rear or front table of the paper cutter. The versatile BTE can fill or empty buffer spaces that eliminate time differences between jogging and cutting and work in combination with gripper systems BFS.

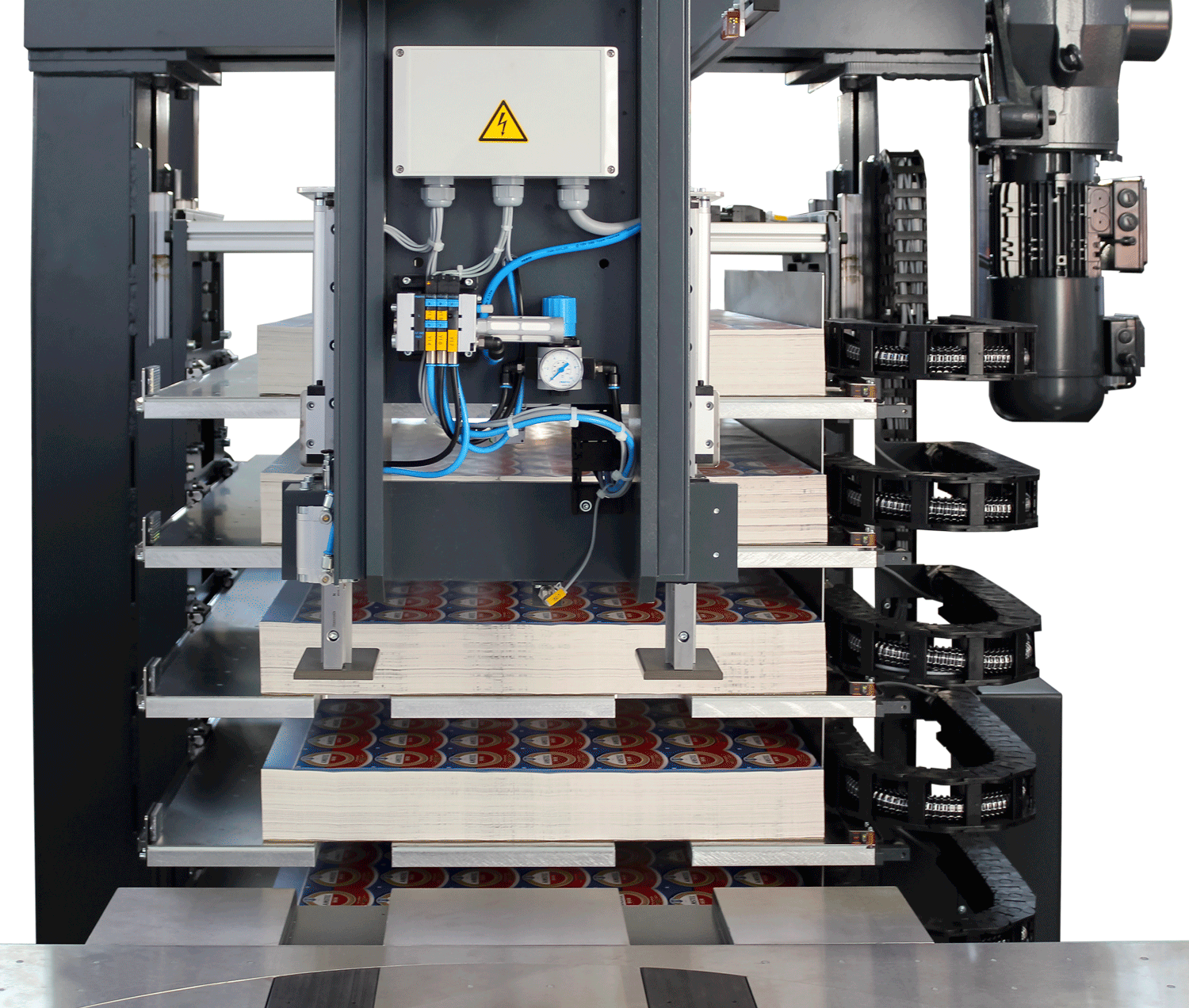

Multi-Layer Rack BMR (Buffer Systems)

The Multi-Layer Rack BMR is a fully-automatic inline solution for buffering layers after inline jogging and before the cutting process. It can work with automatic layer administration, i.e. ”first in - first out” or any other sequence. The vertical buffer space is only limited by the height of the ceiling..

VERTICAL BUFFER SYSTEM BVP (Buffer Systems)

This automatic buffer system eliminates time differences between jogging and cutting. The BVP needs very little space and allows for a constant workflow at the cutting system. It can work with a robotic system or in combination with a pusher system (loading) and a gripper systems (unloading).

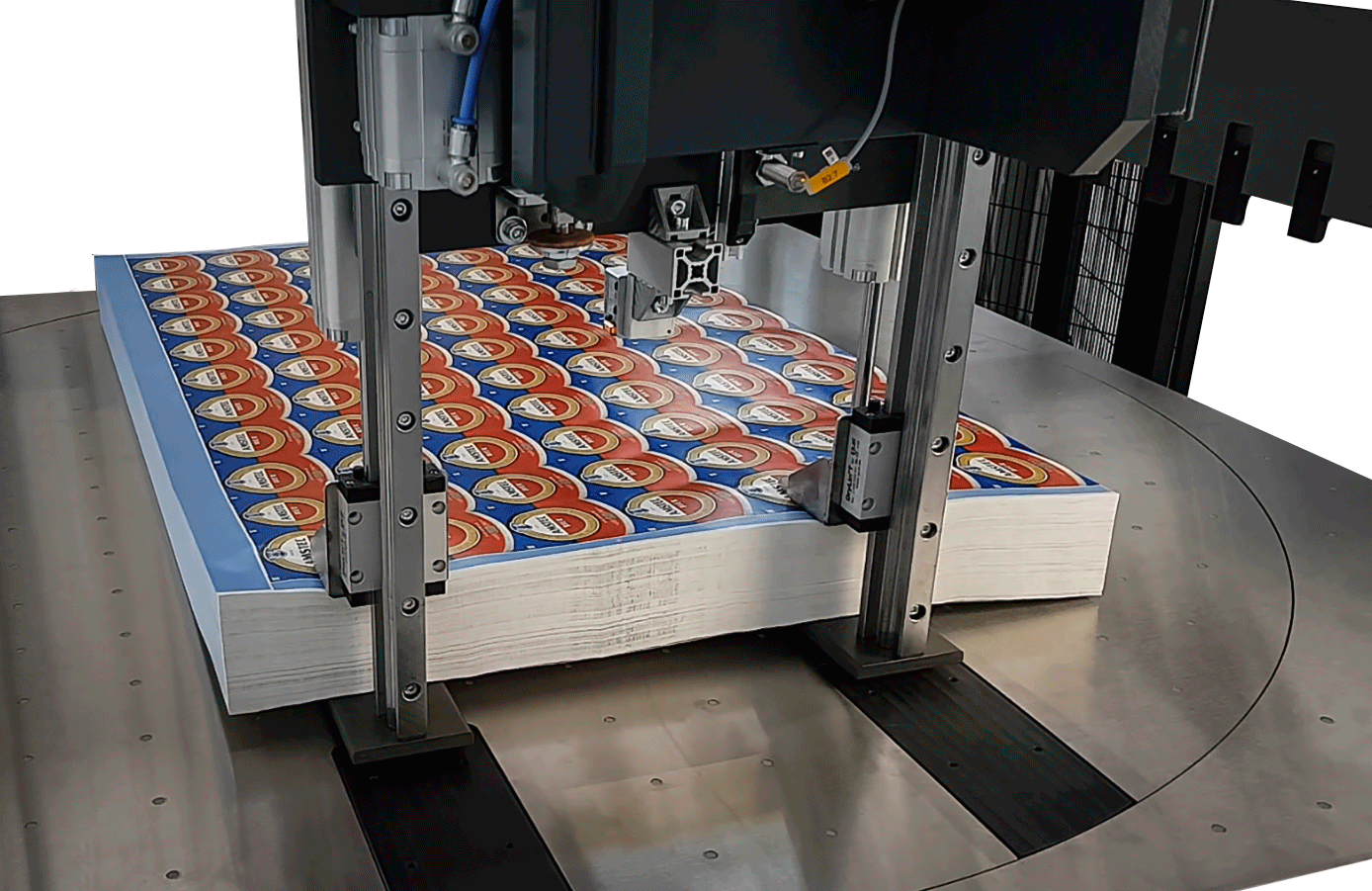

PRESSING STATION BPS

For air removal with very high pressure from within the paper lift prior to cutting, therefore increasing the cutting accuracy.

Available for inline or offline operation. Operator protection with safety light curtain at the front side.

AIR BOARD LIFT BLL

BAUMANN-PERFECTA Air Board Lifts are designed to buffer pre-jogged layers prior to cutting or for storing finished products prior to another finishing process.

MODES OF OPERATION:

INLINE BETWEEN AUTOMATIC JOGGER AND PAPER CUTTER

The Air Board Lift serves as a buffer between jogging and cutting system.

OFFLINE JOGGING STATION

Multiple layers of jogged material can be transferred to the cutting system.

At the cutter the stack is received by another Air Board Lift BLL.

Each layer can either be fed manually at the front of the cutter or by an automatic gripper system for loading into the rear of the paper cutter.

THREE-KNIFE-TRIMMER BP SDY

Versatile off-line Three Knife Trimmer for trimming books, brochures, magazines, and similar products. Optional 4-side trimming device for signatures or loose leaf products.

Two operating modes allow for high versatility between short runs and larger jobs. In return-mode the feeder unit returns the finished products to the operator at the front. In continuous-mode the stack is pushed to the delivery in the back.